Sustainable production

Industry and sustainability in harmony at Lödige Industries

Moving heavy goods efficiently is our core competence. As a globally active industrial company with high energy requirements, we want to be sustainable and create a long-lasting positive impact. Protecting the ecological environment is an important concern of the Lödige family. Reconciling sustainability and industry is important to all of us. The manufacturing of our complex machines and components requires lots of electricity. Hence, we are working hard to reduce the impact of our energy consumption. Today more than 50% of the electricity consumed in our factory in Brasov, Romania already comes from renewable sources. At our site in Scherfede, 100% of our electricty consumption comes from renewable sources, generated on site.

Our own green electricity

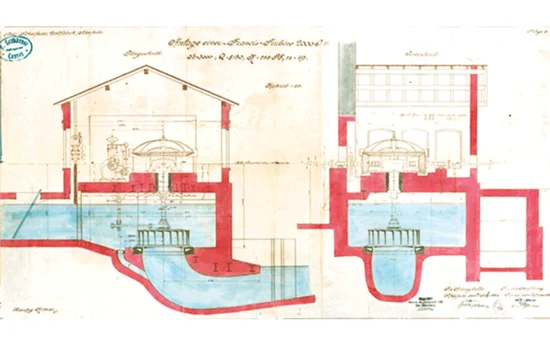

The foundation for a sustainable production was laid in 1965, when the family business, founded in Paderborn in 1948, moved its production to Scherfede. On the premises of a former wool factory, a hydroelectric power plant along the river Diemel allows a continuous supply of regenerative energy. This forms the base of electricity production through its constant modernization. Since last year, our green electricity has also been produced in our own solar park. Thus, 1.190.000 kilowatt hours of regenerative energy are created annually. The production site in Scherfede produces 40 percent more green electricity than it is consuming. The additional energy is fed into the public grid.

Reducing our CO2-Emissions

Thanks to the measures taken, we have already been able to reduce our CO2 emissions at the Scherfede site by 1,700 tonnes since 2017. Our new photovoltaic system contributes 465 tonnes per year. Due to the reduction in the consumption of electricity from fossil fuels, we save 535 tonnes of CO2, through the reduced consumption of gas 700 tonnes of CO2 and 465 tonnes of CO2 through self-generated electricity. In 2021, the savings are expected to amount to 2,000 tonnes of CO2.

Fish ladder

The installation of a fish ladder allows the upstream movement of the aquatic life and received the Environmental Protection Award (German: Umweltschutzpreis) just one year after it was put into operation in 1999.

Energy-efficient LED technology and advanced engineering

Additionally, we are continuously reducing our electricity consumption at the Scherfede site by using energy-efficient LED technology for both inside and outside of our production halls. With the help of a special lighting concept, we were able to reduce our electricity requirement for lighting by 85 percent. Advanced technology and optimizations ensure further savings in machinery and production processes. Since 2017, our total electricity consumption at our Scherfede production site has been almost halved. Gas consumption has also been reduced by 40 percent. With the energy saved, around 200 households can be supplied with electricity and around 120 households can be heated.

A look ahead

In the near future, the last 8-tonne forklifts still powered by diesel will be replaced by electric models for internal transport. The nightly charging of the forklifts will of course be done with our self-produced green electricity from our renewable sources.

In the next 5-8 years, we plan to renew and save on the heating of the production halls. Heating with regeneratively produced hydrogen is also being examined.

Sustainability is anchored in our company values

As a family-owned company we treat each day’s activity as a long-term investment. Our values guide us in our decision-making and motivate us in our daily work. They help us grow as we take on new challenges. As a global company, our common values connect us and provide the basis on which all of us work – with each other and the world around us. Find out more about what inspires us here.